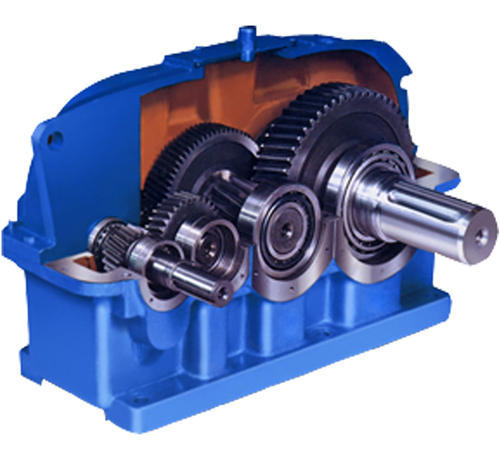

#Parallel-Shaft-Helical-Gear-Box-suppliers #Vidhya-Trading A parallel shaft helical gear box, also known as a parallel shaft helical gearbox or parallel shaft helical gear reducer, is a type of mechanical power transmission device that uses helical gears to transmit rotational motion and torque between parallel shafts. It is commonly used in various industrial applications where speed reduction, torque multiplication, or both, are required. The parallel shaft helical gear box typically consists of two or more helical gears with parallel shafts that are arranged in a compact housing or casing. The gears have helical teeth that are cut at an angle to the gear axis, resulting in a spiral shape. This helical shape allows for smooth and efficient power transmission, with reduced noise and vibration compared to other types of gears. The main components of a parallel shaft helical gear box include: Input shaft: This is the shaft that receives the input rotational motion and torque from the driving source, such as an electric motor or an internal combustion engine. Output shaft: This is the shaft that delivers the output rotational motion and torque to the driven equipment, such as a conveyor, mixer, or pump. Helical gears: These are the gears with helical teeth that transmit the motion and torque between the input and output shafts. The helical gears are typically mounted on parallel shafts and mesh with each other to transfer the rotational motion. Gear housing or casing: This is the housing or casing that encloses the gears and provides support, protection, and lubrication for the gears. It may also include features such as oil seals, bearings, and cooling fins, depending on the specific design and application requirements. Lubrication system: A parallel shaft helical gear box typically requires lubrication to reduce friction and wear between the gears. It may have a built-in lubrication system, such as oil bath or oil splash, or it may require external lubrication. Parallel shaft helical gear boxes are commonly used in a wide range of applications, including conveyors, mixers, crushers, mills, pumps, and other industrial machinery where speed reduction, torque multiplication, or both, are required. They are known for their high efficiency, smooth operation, and compact design, making them a popular choice for many industrial power transmission applications. Proper selection, installation, and maintenance of parallel shaft helical gear boxes are important to ensure reliable and efficient operation.

Chat with us on WhatsApp

×

This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

https://www.vidhyatrading.net/latest-update/parallel-shaft-helical-gear-box-suppliers-vidhya/33

#Parallel-Shaft-Helical-Gear-Box-suppliers #Vidhya...

2023-04-06T05:32:53

#Parallel-Shaft-Helical-Gear-Box-suppliers #Vidhya-Trading A parallel shaft helical gear box, also known as a parallel shaft helical gearbox or parallel shaft helical gear reducer, is a type of mechanical power transmission device that uses helical gears to transmit rotational motion and torque between parallel shafts. It is commonly used in various industrial applications where speed reduction, torque multiplication, or both, are required. The parallel shaft helical gear box typically consists of two or more helical gears with parallel shafts that are arranged in a compact housing or casing. The gears have helical teeth that are cut at an angle to the gear axis, resulting in a spiral shape. This helical shape allows for smooth and efficient power transmission, with reduced noise and vibration compared to other types of gears. The main components of a parallel shaft helical gear box include: Input shaft: This is the shaft that receives the input rotational motion and torque from the driving source, such as an electric motor or an internal combustion engine. Output shaft: This is the shaft that delivers the output rotational motion and torque to the driven equipment, such as a conveyor, mixer, or pump. Helical gears: These are the gears with helical teeth that transmit the motion and torque between the input and output shafts. The helical gears are typically mounted on parallel shafts and mesh with each other to transfer the rotational motion. Gear housing or casing: This is the housing or casing that encloses the gears and provides support, protection, and lubrication for the gears. It may also include features such as oil seals, bearings, and cooling fins, depending on the specific design and application requirements. Lubrication system: A parallel shaft helical gear box typically requires lubrication to reduce friction and wear between the gears. It may have a built-in lubrication system, such as oil bath or oil splash, or it may require external lubrication. Parallel shaft helical gear boxes are commonly used in a wide range of applications, including conveyors, mixers, crushers, mills, pumps, and other industrial machinery where speed reduction, torque multiplication, or both, are required. They are known for their high efficiency, smooth operation, and compact design, making them a popular choice for many industrial power transmission applications. Proper selection, installation, and maintenance of parallel shaft helical gear boxes are important to ensure reliable and efficient operation.

2023-04-06T05:32:53

Keywords

- two

- wear

- pump

- angle

- mills

- mixer

- casing

- choice

- support

- conveyor

- oil bath

- reliable

- bearings

- friction

- features

- crushers

- gear axis

- vibration

- oil seals

- equipment

- protection

- oil splash

- wide range

- Input shaft

- maintenance

- other types

- cooling fins

- spiral shape

- Gear housing

- Output shaft

- installation

- reduced noise

- helical gears

- helical teeth

- helical shape

- Vidhya-Trading

- compact design

- electric motor

- driving source

- compact housing

- parallel shafts

- speed reduction

- main components

- specific design

- smooth operation

- Proper selection

- Lubrication system

- efficient operation

- external lubrication

- torque multiplication

- input rotational motion

- output rotational motion

- application requirements

- internal combustion engine

- other industrial machinery

- efficient power transmission

- parallel shaft helical gearbox

- various industrial applications

- parallel shaft helical gear box

- parallel shaft helical gear reducer

- mechanical power transmission device

- Parallel-Shaft-Helical-Gear-Box-suppliers

- many industrial power transmission applications

Submit Your Enquiry